From Grams to Milligrams: Understanding Analytical Balance Sensitivity

From Grams to Milligrams: Understanding Analytical Balance Sensitivity

Blog Article

In the world of scientific research and laboratory analysis, precision is paramount. High-precision laboratory analytical balances play a critical role in ensuring accurate measurements, allowing researchers to obtain reliable data. These sophisticated instruments have the ability to weigh substances with exceptional sensitivity, making them indispensable in various applications, from pharmaceutical formulations to quality control in manufacturing.

Understanding the nuances of balance sensitivity is crucial for anyone working in a laboratory setting. The difference between grams and milligrams may seem trivial, but in analytical chemistry, even the smallest miscalculation can lead to significant errors. W&J Instrument stands at the forefront of this technology, providing a diverse range of electronic balances, moisture analyzers, and viscometers. Their commitment to quality and innovation ensures that laboratories are equipped with the tools necessary for precise measurements and improved accuracy in research.

Importance of Analytical Balance Sensitivity

The sensitivity of an analytical balance is crucial for achieving accurate and reliable measurements in laboratory settings. High-precision balances can detect minute changes in weight, often down to the milligram or even microgram level. This fine sensitivity is essential in fields such as pharmaceuticals, where minute variations can significantly impact drug formulation and quality control. A highly sensitive balance allows researchers to ensure that they are using the correct amounts of substances, leading to reproducible and valid results.

Moreover, the ability to measure small quantities accurately is vital for cost efficiency and resource management in a laboratory. With a sensitive analytical balance, scientists can minimize waste by ensuring that even the smallest amounts of materials are measured correctly. This is particularly important when working with expensive or rare substances, where precision is necessary not only for the integrity of experiments but also to optimize the usage of valuable resources.

In addition to improving accuracy and efficiency, the sensitivity of analytical balances plays a significant role in compliance with regulatory standards and quality assurance protocols. Many industries are required to adhere to stringent guidelines that mandate precise measurements for safety and efficacy. Using a reliable and sensitive analytical balance, such as those manufactured by W&J Instrument, enables laboratories to meet these regulations and maintain high standards of quality control, thereby building trust with clients and regulatory bodies alike.

Features of W&J Instrument Balances

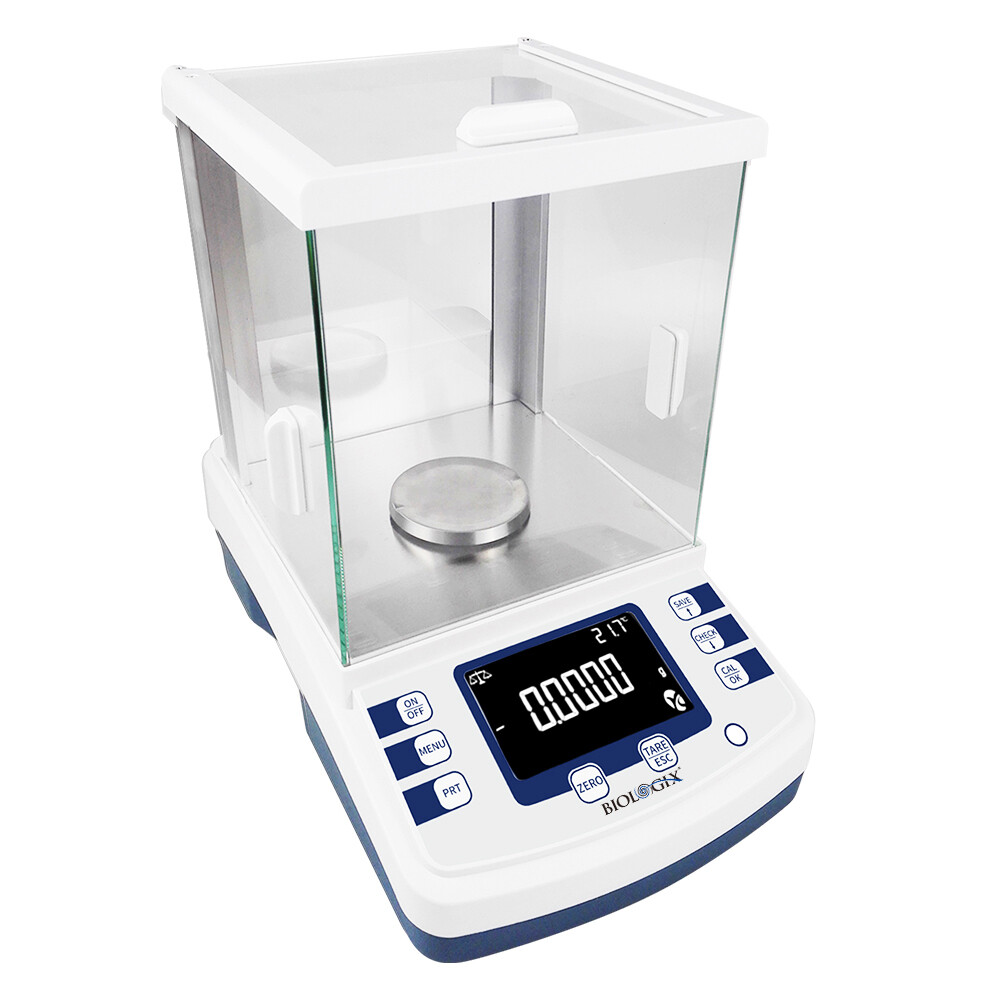

W&J Instrument balances are engineered with cutting-edge technology to provide unparalleled precision in high-accuracy measurements. Their designs incorporate advanced load cell systems that enhance sensitivity, allowing for weight detection in both grams and milligrams. This sensitivity is crucial for laboratories where minute changes in weight can influence experimental outcomes. Each balance is calibrated to ensure that it delivers consistent results, making them an ideal choice for both research and quality control settings.

In addition to accuracy, W&J balances are user-friendly, featuring intuitive interfaces and clear digital displays. This simplicity allows users to navigate settings and obtain readings with minimal effort. Many models come equipped with advanced connectivity options, such as USB and Bluetooth, enabling easy data transfer and integration with laboratory software. The robust build quality of these balances ensures they withstand the rigors of daily use while maintaining precise performance.

W&J Instrument also focuses on safety and utility in their balance designs. Many models are equipped with draft shields to prevent external influences that could affect measurement accuracy. Furthermore, features such as automatic internal calibration and overload protection contribute to the longevity and reliability of the instruments. As a result, W&J balances not only meet the stringent demands of modern laboratories but also provide an efficient solution for various weighing applications.

Comparative Analysis of Grams and Milligrams

The distinction between grams and milligrams is fundamental in the realm of analytical balances. Grams, being a larger unit of measurement, are often used for weighing bulk samples or larger quantities in laboratories. In contrast, milligrams are used for measuring smaller quantities, which is essential in fields such as pharmaceuticals and chemistry where precise dosing is critical. Understanding this differentiation is crucial for researchers and technicians who rely on accuracy in their experiments.

The sensitivity of analytical balances plays a vital role when weighing in either grams or milligrams. High-precision balances, manufactured by companies like W&J Instrument, are capable of measuring mass with exceptional accuracy, often down to 0.01 milligrams. This capability is particularly important in experiments where even the slightest discrepancy can lead to significant variations in results. Analysts must ensure that their balance is suitable for the scale of measurement they intend to use, as using a balance not designed for milligram precision can lead to errors.

Commercial Scales for Laboratories

Moreover, the calibration and maintenance of analytical balances impact their performance in both grams and milligrams. Regular calibration is necessary to ensure that the balance provides accurate readings, and this is particularly critical when switching between different measurement scales. Laboratories often conduct routine checks using certified weights to confirm the reliability of their measurements. For optimal results, users must be knowledgeable about the operational ranges and specifications of their analytical balance, ensuring they achieve the desired precision for their specific applications.

Applications in Laboratory Settings

High-precision analytical balances are indispensable tools in various laboratory settings, playing a critical role in the accurate measurement of small quantities of substances. In pharmaceutical laboratories, they are used to ensure precise formulation of medications, where even slight deviations can impact efficacy and safety. Accurate weighing is pivotal in these environments, facilitating compliance with strict regulatory standards and promoting high-quality outcomes in product development.

In research laboratories, analytical balances are utilized for diverse applications, including chemical analysis, material characterization, and quality control. Scientists rely on them to measure reactants, catalysts, and compounds with extreme precision, which is essential for obtaining reproducible and reliable results in experiments. The sensitivity of these balances ensures that even minute variations in mass can be detected, enabling researchers to draw meaningful conclusions from their work.

Additionally, manufacturing and quality assurance facilities benefit from high-precision balances in their processes. These balances are critical for the formulation of consistent products, quality checks, and process optimization. By ensuring that ingredients are weighed accurately, companies can enhance production efficiency, reduce waste, and maintain product quality. In this way, the role of analytical balances extends beyond simple measurement, contributing to overall operational excellence in various industries.

Report this page